OXIA Cycles

Everything happens in Murcia. Just as Salzillo carved baroque imagery to illustrate the people's faith, Carlos now sculpts bicycles, also for everyone. Custom pedals on a steel frame.

It is not a store where you buy a bicycle approximately your height. It is a workshop where the bicycle that your body needs is born. Let biomechanics choose, not the market. Craftsmanship applied to sport, because we all deserve a bike like this.

As he says: “My work is an endless creative journey. Each project allows me to explore new possibilities, to learn and perfect my technique. It is a passion that drives me to continue creating unique bicycles that not only meet the needs of my customers but also reflect my vision and style.”

Let's see what else Carlos, owner and ideologist of this very original project, tells us:

Hello Carlos, what prompted you to start a plan like this?

It all started when I decided to buy a new bicycle. I couldn't find anything that convinced me in the manufacturers' catalogs, so I opted for a steel one, with a rigid fork, without suspension or gears, a pinion, and a chainring. That bike made me rediscover the pleasure of riding.

Then I contacted Andrés Arregui, I trained in his workshop and when I returned, I began to set up my project, thinking about manufacturing my bicycles and making some for friends. After the 2020 pandemic, I saw it clearly and began to move decisively with OXIA.

Do you have a favorite design?

I love my current MTB, I am in love with the OXIA LOLA model. A few days ago I delivered a road bike that drives me crazy for its style: sober, with classic lines and a spectacular assembly of components. I already have the next gravel race in mind and I don't think I'm going to give up on it.

Can we apply the word “sustainable” to any step of your work?

Everything is sustainable at OXIA, from the steel to the paint. All the material I use is recyclable and does not pollute. In the workshop, I separate the garbage just like at home and I have a box where I put the scrap steel to recycle. If I use any solvent to clean non-sustainable parts or products, I store them to take them to the nearby clean point. Recycling is effortless for me and I do everything I can to contribute. David, my painter, follows the same guidelines: he uses water-based paints and recycles 100% of the materials used in the paintings.

Caring for the environment is one of OXIA's fundamental values. The steel we use is fully recyclable, which helps reduce our carbon footprint by 70%.

What is your favorite corner of the Murcia region?

Calblanque in winter and Sierra Espuña in summer. If I had to highlight one, it would be Cala Aguilar. It is on the coast of Cartagena and can be reached by boat or after a very hard walk. Getting to that wonderful environment and feeling the disconnection from the hustle and bustle and stress is healing for me. Any place that gives me that feeling is my favorite.

And, your favorite place where you have arrived by bicycle?

In the Alps and the Pyrenees I have traveled spectacular roads. In Spain, I would choose the Campos de Hernán Perea, in Cazorla, for the peace that is breathed, the environment, the location, and its characteristics.

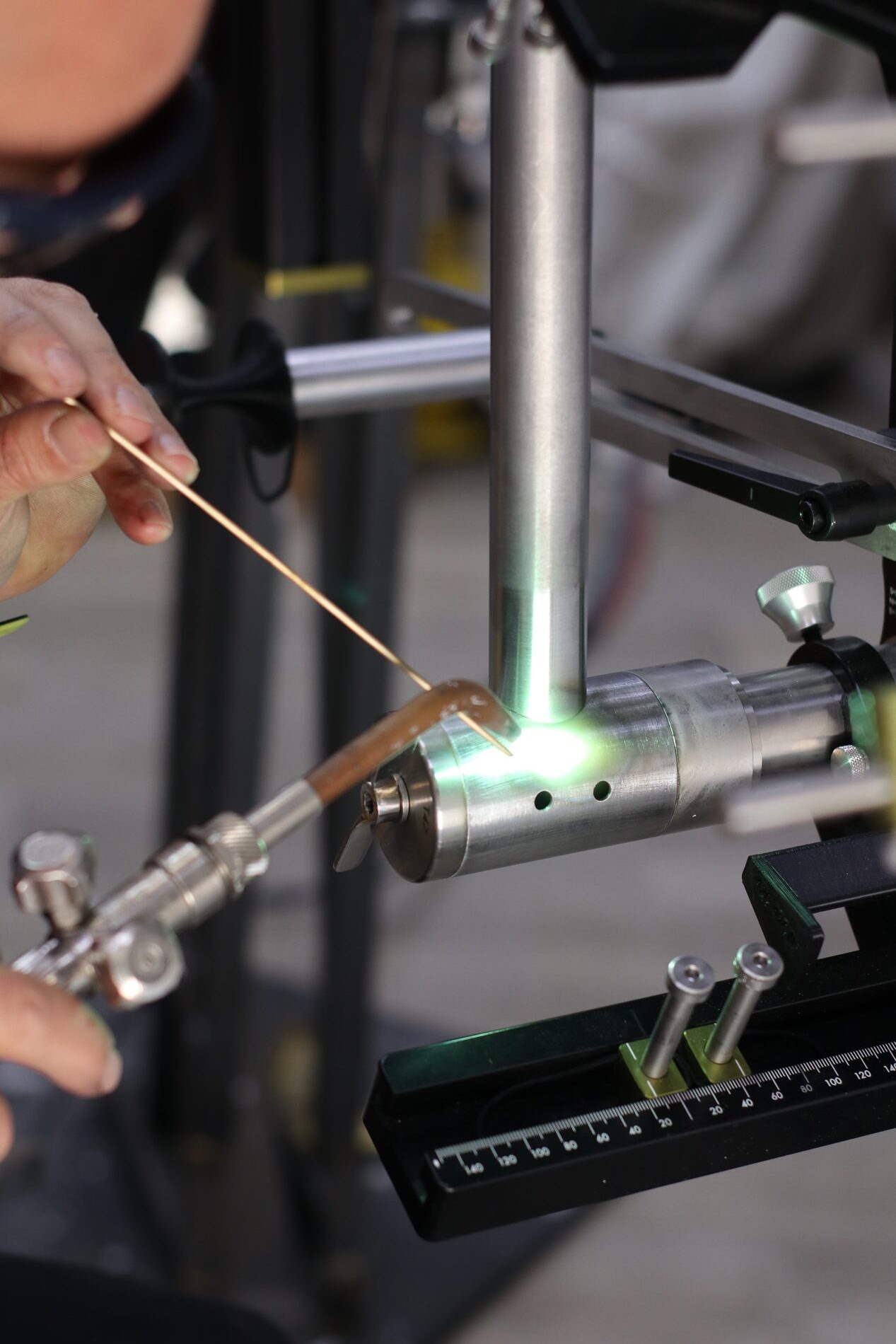

Why steel?

Sustainability as I said, but also romanticism. Steel is one of the best materials for craftsmanship. With it, I can create fully customized high-performance bicycles at an affordable price.

The current steel used in the manufacture of bicycles is the result of unimaginable R&D work. Thanks to this, frames with top-level characteristics are achieved in all aspects: weight, poise, balance between stability and agility, reactivity, comfort, and absorption.

Steel has great fatigue resistance and, when well worked, provides extraordinarily long-lasting frames. A steel bicycle can accompany you for many years.

The standard measures the market imposes are not part of the OXIA essence. How much important is biomechanics in your manufacturing process?

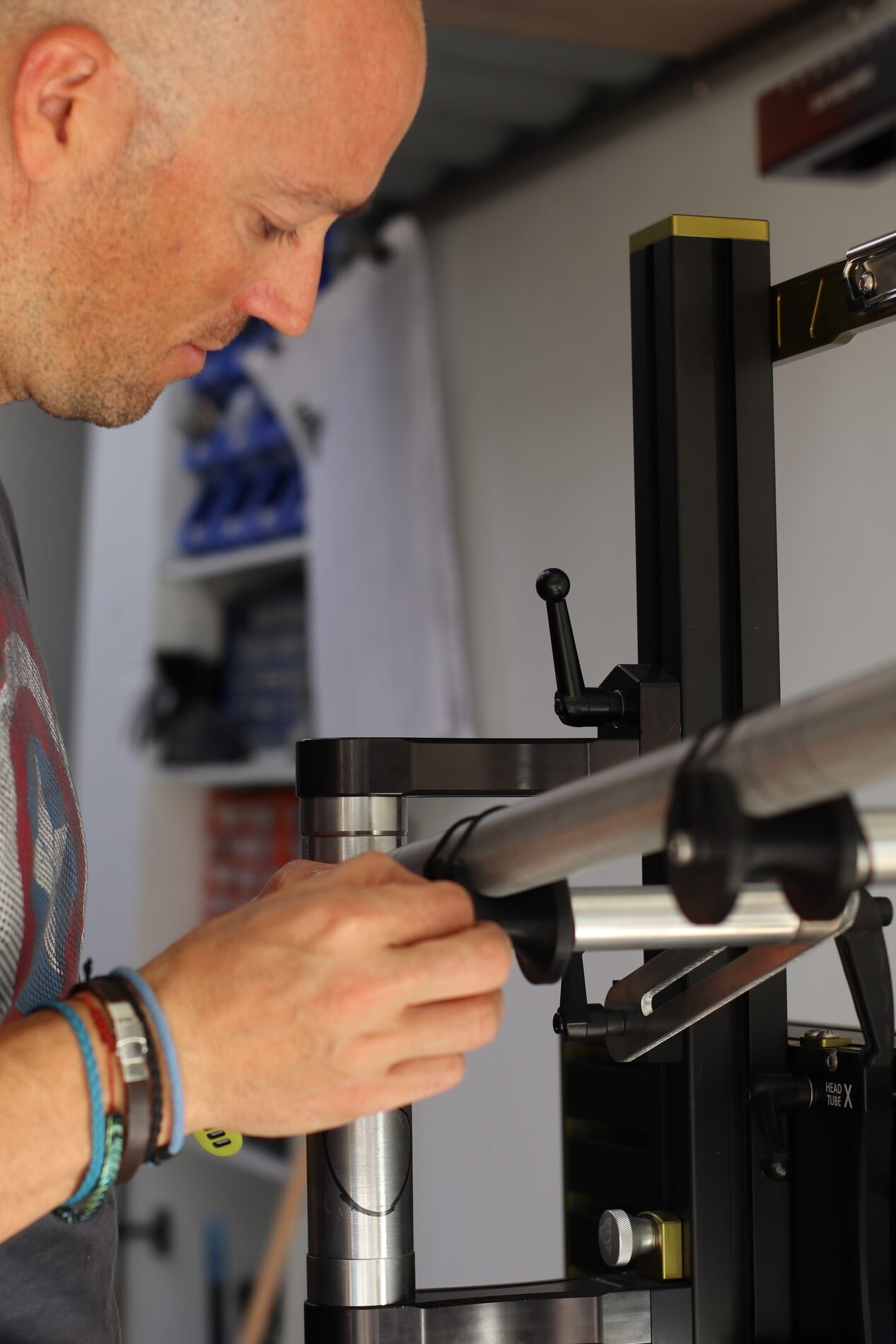

It is essential to achieve perfection in the fit of the bicycle for the rider. Comparable to a tailored suit. The tailor meticulously takes all the body measurements, prepares the patterns, cuts the fabric to the necessary size, and sews everything so that it fits perfectly, so perfectly that you feel like you are not wearing anything.

The measurements are taken by the biomechanics, I am the tailor, I design the geometry which is the pattern with which I cut the tubes, I glue them, and the final result is that the client gets on the bike in a position so natural that you may feel comfortable.

The behavior of the bicycle is as important as the position of the cyclist. If it feels comfortable, but the bike does not perform the correct movements when asked, we can say that the job is not done well.

Our previous protagonist, Javier Garduño – EdD, left a question for the next one. Here it goes: “How do you think AI will affect your work? Will it be a positive change, or on the contrary an enemy to face?”

It would benefit me. The AI does not yet cut and weld tubes by hand, but it could design the geometry requested so that the bicycle behaves as required and the cyclist feels comfortable. This translates into a significant reduction in time and effort invested in the design process.

If it were the last time you rode a bike, who would you go on that route with?

I would take a walk with the whole family and a few very selected friends, although I would miss someone who is no longer here and would be an important part of the group. Some walk on the beach looking for a good place to have a few beers, eat relax and enjoy the day. I'm content with little.

Do you have any hobbies outside of work?

Yes, several. My ninety-minute walk every morning with my dog in the mountains, to start the day full of energy.

I also love watching sporting events on television with my wife (Olympics, winter sports, some Paralympic events, rugby...) and I like plants, especially the complex world of bonsai, to which I don't dedicate as much time as I should. , that's why I have hard species that can withstand my way of caring for them (mulberry, Aleppo pine, Japanese maple, carob trees...).

What is the farthest place you have shipped any of your bikes?

Mexico D.F.

What is your vision for OXIA Cycles in the coming years?

I am passionate about thinking and basing my actions on what I have experienced and what I want to achieve. Therefore, I have quite ambitious plans for the future. Although I prefer not to reveal details, I can say that I aspire to become a reference in the world of handmade bicycles.

Can you leave us a question for the next protagonist?

Sure: “If you had the option to travel to your past, what would you tell yourself?